1.Production introduction

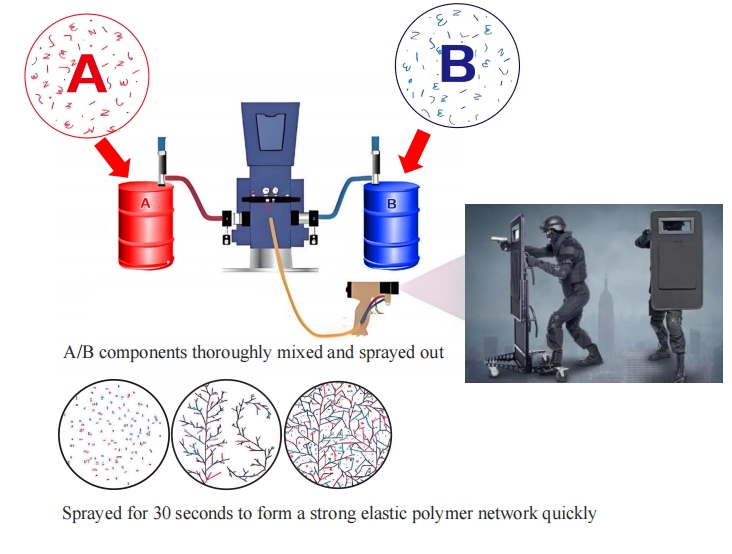

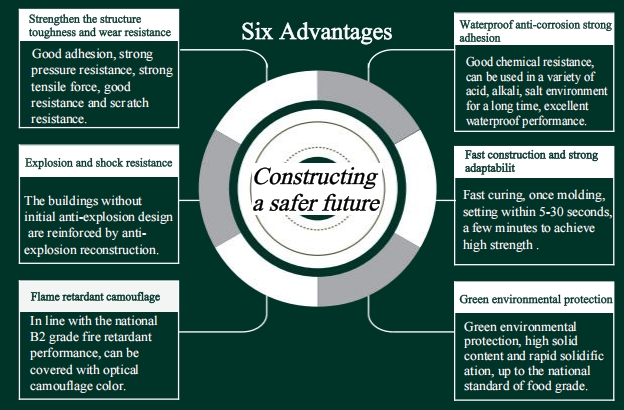

Elastomer Armor Coatings (EAC) is a high molecular weight elastic coating consisting of two primary components: Component A, anisocyanate (-NCO) for enhancing hardness, and Component B, an amine(-NH2) for imparting flexibility. These components react rapidly upon mixing and are applied via spray application without the need for acatalyst. This results in the formation of a robust, resilient polymer network that exhibits strong adhesion, effectively mitigates cracking near stress points, and offers outstanding resistance to impact, corrosion, wear.explosions, and fire. Additionally, the coating can be utilized in combination with an oil-swelling repair coating.

2.Technical principle

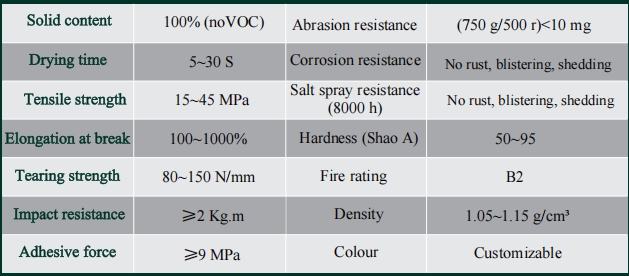

3.Product performance

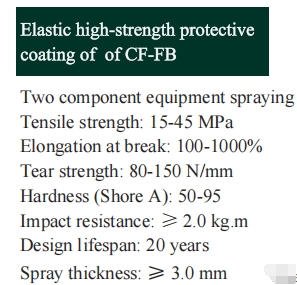

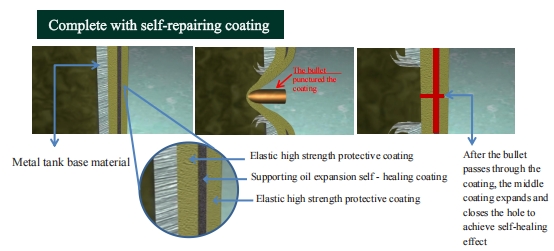

4.Introduction of supporting products

Test conditions

Substrate: metal fuel tank

Coating type: elastic high-strength protective coating matching oil self-healing coating Coating thickness:3 mm

Test bullet 7.62 mm

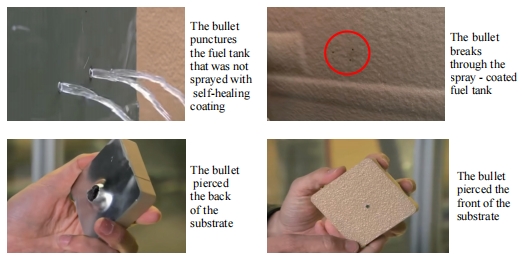

Test results:

After the oil tank without self repairing coating was punctured, the oil leaked completely.

After the spray self-healing coating oil tank was punctured, there was no oil leakage.

5.Field of protection

Protection of important building facilities

Camouflage and protection are carried out for the appearance of important buildings, warehouse facilities, Bridges, ports and other facilities to play the role of explosion prevention and flame retardant, alleviate the blast wave, prevent debris splash, reduce the damage of buildings and personnel.

Vehicles are equipped with camouflage protection

Paint for vehicles, important workshops, ete,, play the role of high and low temperature res istance, protection, camouflage, ete., greatly improve the ability of explosion resistance, fire prevention and explosion proof.

Oil equipment protection

Spray protection is provided for refueling vehicles, field oil depots, mobile gas stations, container equipment and other equipment, which plays the role of fire prevention and flame retardant, breakdown self repair, explosion-proof and other functions.

Explosion-proof oil depot facilities

For the oil storage tank, oil pipeline, pump room, equipment warehouse, oiltank coating and other facilities to paint, play the role of high temperatu reresistance, protection, camouflage, effectively improve the oil storage Facilities fire and explosion proof, anti-corosion and moisture-proof.

Protection of chemical enterprises

For the comprehensive control room of chemical enterprises, the anti-explosion wall is added, the anti-explosion transformation of the cabinetroom of the control room of the synthesis workshop, the anti-explosion transformat ion of the dispatching control building.

Personnel protection

For safety helmet, explosion-proofshield, bullet proof board and other surface spray protection, play a role in explosion-proof, anti-storm and other, improve the protection performance.